アウトドアライフにおける“シェル”は、誰にとっても必要なアウターウエアである。ゴアテックスに代表される防水透湿性素材のウエアから、防水性のみの合羽まで様々な種類のものがある。なかでも、現在、〈ザ・ノース・フェイス〉がシェルのひとつの生地として、既存の発想を変え、開発に取り組んでいる最新製織技術に『ヒューズフォーム』と呼ばれる織物がある。1枚の生地の途中でもう1枚別の生地に切り替わるという最新テキスタイルだ。この1枚の生地だけで、ウエアの強度や機能に革新的な変化が生まれる。例えば、バックパックを背負ったときの肩の強度を上げるために、いままでであれば、型紙どおりに生地を断ち、縫製し、さらに縫い目の隙き間から水分や風が入ってこないようにシームテープを貼っていたが、その一連の作業すべてがなくなる。一見すると普通のシェルだが、よく見ると「縫い目がないじゃないか!」となるわけだ。しかも、必要なパーツに応じて自由自在に用いることができる。この『ヒューズフォーム』を考案したのは、〈ザ・ノース・フェイス〉だが、その難しい生地の生産を高度なプログラムをもって可能にしたのは、石川県の中能登にある織物工場だった。中能登には、伝統産業の「能登上布」という薄く滑らかな麻織物があり、古くから織物の町として発展した地域で知られている。

A “shell” is a must have piece of outerwear in the world of outdoor life. From the Gore-Tex representative waterproof and breathable wear to the waterproof only rain coat, there are a variety of items. The North Face has revolutionary new weaving technology for creating a single piece of shell fabric called “Fuse Form”. It is a textile that weaves two pieces of fabric together to form one single fabric. You get a combination of the highest strength and functionality from this one piece of innovative fabric. For example, when raising the strength of the shoulder region of a shell when carrying backpacks, the entire process of the pattern cutting, sewing, fixing the seams, and sealing with seam tape, completely gets replaced. At a first glimpse, it may seem like a regular shell, but there will be no seam. In addition the needed components are completely unrestricted. It was The North Face that first had the idea, but it was the textile factory in Ishikawa prefecture Japan that made the program possible. In Nakanoto, there is traditional hemp fabric, “Notojofu”, facility and the town itself is world recognized for producing textiles.

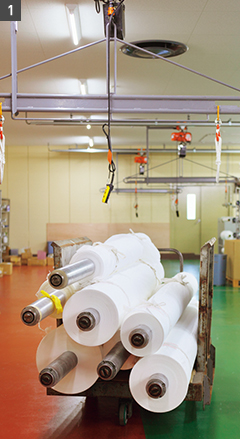

巨大な糸巻きを“ビーム”という。製品の規格に合わせてタテ糸を揃え、織布用のビームに巻き取る工程「巻返し」の作業場だ。音楽を鳴らしながら無人でビームを運ぶ自動搬送ロボットもいた。

A gigantic spool of thread is called a “beam.” This workspace is for winding the warp threads onto the beams. With music playing in the background, there was also a robot that helped transport the beams.

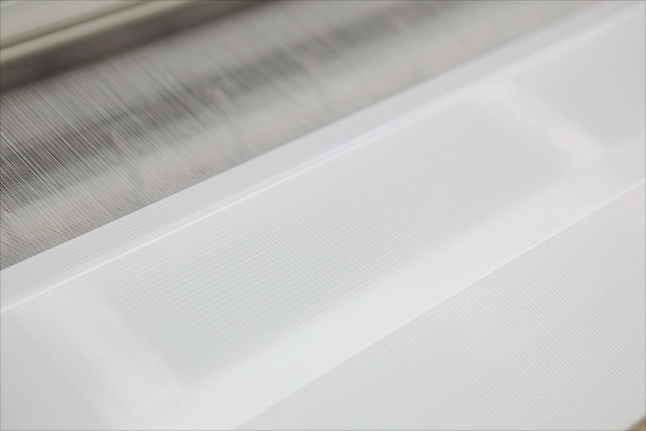

織布用のビームに巻き取られている最中のタテ糸がこの写真。デリケートな細い糸になるほどスピードが上げられない。見た目は美しいが、張力、糸の欠点を逃さないように見つけていく大変な作業。

This picture shows the warp threads being wound onto the beams. Speed must be regulated as threads are extremely delicate and fine. It is a beautiful sight but tough job in quality control of the threads.

1週間から10日かけて作られたタテ糸を、織り機にセットする最終段階では、人の手で細かい作業を行う。タテ糸からヨコ糸への橋渡しという重要な作業には、思いがけず多くの手作業が入っていた。

Warp threads were created in a process that takes one week to ten days and the final process requires hands on dexterous work. There are many hands on steps in the process of combining the warp and weft threads.

この『ヒューズフォーム』の担当者の会話の中に頻繁に“デニール”という単語が出てくるのは、デニールという糸の太さの単位が、最先端の製織技術では重要な基準になるからだ。

「デニールの数値が小さくなるほど、細い糸になります。9000mの長さでわずか1gというのが1デニール。〈ザ・ノース・フェイス〉の最軽量のダウンの生地は7デニールで織られていますが、7デニールまでに細くなると肉眼では判別しづらく、後ろに黒い紙を置かないと糸が見えないレベルです。『ヒューズフォーム』はそのダウン生地よりも太い20デニールで織られていますが、それでも糸だけでは触っている感覚がないほどです。この新しい生地の製作には、お話をいただいてからイメージを形にするまでに半年かかりました。設計書を書き上げるだけでも1ヶ月。しかも、その織物組織図は他の生地に比べて3倍も長い。タテ糸は同じ糸を使い、ヨコ糸に素材や糸の太さに変化をつけて織っています。この変化のつけ方が難しく、同じデニールでも異素材のもので張力が異なればシワが入るし、より細い糸になると毛羽立ったり切れてしまったり。当初、工場で使っている織機では、理想とする織り方ができなかったので、タテ糸そのものに特別な工夫を凝らしました。生地の切り替えに大きな違いを生み出すためには、糸の選定のほかに、平織、綾織(ツイル)、朱子織(サテン)など、生地の織り方も組み合わせることが必要です。うちの工場で行うのは生機(加工前の織り立ての生地)までなのですが、その後に染め屋さんで色を入れる際の、生地の色ののり方まで考えて糸や織り方も選ぶので、まさに試行錯誤の連続です。でも、なんとか形になるとうれしいですよね。まだまだ新しいことも実験中です」

『ヒューズフォーム』は、まだシェルの可能性のひとつに過ぎない。今後あっと驚くような素材の組み合わせや新機能を持ったシェルが出てくるに違いない。技術の革新がアウトドアのフィールドで笑顔を生み出すのだ。

The word that comes up frequently in conversations with the project manager of Fuse Form is “denier.” Denier is the thread thickness measurement unit and because this is a cutting edge weaving technology, it is a key terminology.

“With denier, the lower the number the finer the thread. A 9000m long thread that is only 1g is 1 denier. The North Face’s lightest down fabric is 7 denier and to the point where it is hard to see with the naked eye. The Fuse Form is thicker and woven with 20 denier threads, but even then the thread is extremely small and hardly has a sense of feel when touched. It took half a year to put the image into form from first hearing the idea of the new fabric. Creating the design specifications took a month alone. That in itself is three times the standard. All of the warp threads are the same, but the weft threads are mixed in both size and material. This is an extremely difficult process as even if the denier is the same, a difference in elasticity will cause wrinkles, and the smaller the threads the easier it is to develop tears. At first, we were unable to utilize our preferred weaving methods with the current machinery, so we came up with an innovative technique that utilized a combination of both the regular warp threads and special warp set threads. For producing differences in fabrics, in addition to thread selection, they had to experiment with weaving various fabrics like satin and twill. The fabrics are produced up until the raw fabric stage at this factory and sent out to a dyer to be colored, thus everything is considered in the beginning process. It was a long continuation of trial and error. But, everything is looking good now and we are excited to be trying even newer things!”

“Fuse Form” is currently only being used for shells. Further revolutionary shells made from a surprising mix of fabrics and new technology will surely be released in the future. Technology innovation helps produce smiles in the outdoor world.

“Fuse Form” is currently only being used for shells. Further revolutionary shells made from a surprising mix of fabrics and new technology will surely be released in the future. Technology innovation helps produce smiles in the outdoor world.

生機に仕上げる製織作業。エアジェットの機械音は想像以上にけたたましい。

Weaving raw fabric. Extremely shrill sound from the air jet machine.

1. 染める前の生機と「FUSE FORM VERT JACKET」の完成品 2. 生機完成。3.『ヒューズフォーム』は様々な人の協力で作られている。

1. Raw fabric before dyeing and a completed FUSE FORM VERT JACKET. 2. Completed raw fabric. 3. Fuse Form project manager.

縫製箇所を限りなく減らすことで防風性を向上させた超軽量ウィンドシェル。1000mmの耐水性で、並の雨はOK。

Ultralight wind shell with minimal sewing seams and high wind resistance. 1000mm water-resistant suitable for normal rainfall.

no.: NP71442

price: ¥10,000

size: S, M, L, XL

weight: 80g

color: Drummer Blue,

Acid Yellow, Urban Navy,

Luna Ice Gray, Black

price: ¥10,000

size: S, M, L, XL

weight: 80g

color: Drummer Blue,

Acid Yellow, Urban Navy,

Luna Ice Gray, Black

『ヒューズフォーム』とは、1枚の途中で生地組織が変わる織物のことをいう。縫製箇所を最小限にし、破損を軽減しながら強度を向上、ウエアの軽量化を実現させる最新製織技術。

There are two ways to get wet when on the mountain. First is rainfall, second is from sweating on the inside. The Vent Shell has waterproof, anti-wind, and breatha-bility functionality suitable for trail runners, speed hikers, and various activities in humid Japan.

For one day trips, this single item covers both your rain wear and wind shell necessities.

For one day trips, this single item covers both your rain wear and wind shell necessities.

山に入って“濡れる”要因はふたつ。雨で外側が濡れるのと、汗で内側が濡れること。トレランはもちろん、スピードハイキングなどの運動量の多い人や、気温の移り変わりや湿度の高い日本の山に適したミッドレイヤーで、防水性、透湿性、防風性を併せ持つのがベントシェル。日帰りならば、これ1枚でレインウエアとウィンドシェルの2枚を持っていく必要もなくなる。

Fuse Form is taking one fabric and weaving it with another. It is a cutting age innovative weaving technology for reducing sewing seams, strengthening fabric, and weight reduction.